The W 35 CNC is usually a common CNC precision lathe that WEILER has produced for instruction functions. It is particularly compact, can be used for an array of programs and is supplied with the most up-to-date Siemens ONE1 Manage, ShopTurn user interface in addition to a 19-inch touchscreen.

Allow or Disable Cookies Should you disable this cookie, we won't be able to help you save your Tastes. Which means that each time you take a look at this Web-site you must empower or disable cookies yet again.

Whether or not you’re working within a toolroom, a high-tech market, or anywhere in between, these machines present the features, technical specs, and trustworthiness essential to make certain your assignments are done for the highest benchmarks of precision and excellent.

The linear glass scales to the X1, Y1, and Z1 axis slide is furnished as typical, for ensured high accuracy machining and repeatability.

Naturally, We have now the right holders to suit your needs and much more: as a price-productive solution we have compiled excellent tool holder deals.

Each during the entry-amount variety with the attractively priced CLX styles and in the high-tech segment with the verified CTX and NLX lathes, DMG MORI sets criteria from the machining of demanding precision workpieces.

The CNC lathe headstock is actually a basic element that assures the exact and productive Procedure in the machine. By housing vital factors like the spindle, chuck, and bearings, the headstock supplies the necessary assist and rotational electric power to execute numerous turning functions.

Improved Area Finish: Sliding head lathes can reach outstanding surface finishes in comparison to regular lathes. That is very important in industries wherever aesthetics or specific operation of the machined factors are critical.

The highest accuracy in machining is categorized by tolerance grades, starting from IT01 to IT18. The lessen the selection, the higher the precision. For the most demanding programs, grades as exact as IT01 are wanted, which means the parts are machined to tolerances within thousandths of the millimeter.

The flexibility of sliding head producing makes it ideal for a wide selection of industries, which includes although not limited to:

The spindle, mounted within the headstock, is the main rotating aspect that holds the workpiece set up all through machining. Spindles are created with precision taper roller bearings and ball bearings for smooth and steady rotation.

Regular cleaning with the headstock and spindle place is vital to eliminate debris, coolant residue, along with other contaminants that may accumulate all through machining operations. This assists retain the integrity in the bearings and lower the potential risk of contamination-connected failures.

Kingsbury supply highly advanced six spindle sliding headstock automatic lathes which offer unparalleled manufacturing performance and performance by enabling for numerous parts being machined simultaneously. These machines are generally used to manufacture high excellent view factors, electrical fittings, clinical and armed forces elements.

A sliding headstock automatic lathe is really a highly more info versatile machine that is made for efficient and accurate generation, with speedy cycle periods. Outlined beneath are a lot of the essential advantages of a sliding headstock automatic lathe:

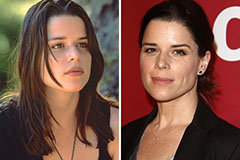

Neve Campbell Then & Now!

Neve Campbell Then & Now! Angus T. Jones Then & Now!

Angus T. Jones Then & Now! Kelly McGillis Then & Now!

Kelly McGillis Then & Now! Joshua Jackson Then & Now!

Joshua Jackson Then & Now! Lacey Chabert Then & Now!

Lacey Chabert Then & Now!