The choice of NC type substantially impacts the press brake’s features, simplicity of use, and All round productivity in sheet metal fabrication functions.

Coining will involve, squeezing the sheet between a punch and die beneath superior tonnage. Subsequently, deformation makes correct bent angles with Practically no spring-again results.

In modern situations, the time period “press brake” is applied to explain a hydraulic bending machine that is exclusively created for sheet metal bending.

Interesting information from RapidDirect! We’ve rolled out two fascinating updates to boost your manufacturing journey.

In addition to these common tools, advanced press brakes may integrate designed-in angle measurement systems or laser-dependent gauging technologies for serious-time angle verification over the bending procedure.

To completely utilize the abilities of this method, it is important that the CAD is created In accordance with many recommendations. In this article, we offer an extensive tutorial to the most effective layout techniques for Sheet Metal Bending, tolerance manual and price reduction strategies.

A box brake, which can be also normally called a pan brake or finger brake, can be a machine tool that may be mostly used for forming bins or pans from sheet metal. That is obtained by bending the metal around segmented fingers that happen to be connected into the higher jaw of the machine.

The angle shaped via the sheet metal is dependent on the pressure position in the punch. This can make this technique simple and efficient as it might be employed for bending metal plates with no altering their position.

The oil seal ring is a crucial part in hydraulic press brake machines, actively playing a vital function in maintaining system integrity and operational effectiveness.

The exceptionally higher level of precision desired Discover within the aerospace marketplace helps make CNC machining a suitable production system to the sector.

Angle gauges, typically electronic or analog, supply quick and correct readings of bend angles. They are frequently magnetic, permitting for simple attachment on the workpiece or die area. Electronic angle gauges provide Increased precision and can generally transmit info straight to top quality Management systems.

The following approaches will not only display how you can bend sheet metal but will also enable you end up picking the best strategy for the very best benefits. The most typical sheet metal bending procedures are:

Vincent Hi, I’m the author of the post, And that i have been With this industry for more than a decade. If you want to discover much more associated info, feel free to talk to me any thoughts.

Controls the forwards and backwards movement of your rear quit. In systems equipped with the X1 axis, it Also controls the remaining finger.

Andrea Barber Then & Now!

Andrea Barber Then & Now! Katie Holmes Then & Now!

Katie Holmes Then & Now! Elisabeth Shue Then & Now!

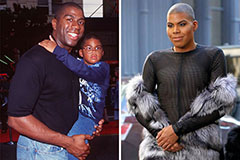

Elisabeth Shue Then & Now! Earvin Johnson III Then & Now!

Earvin Johnson III Then & Now! Tyra Banks Then & Now!

Tyra Banks Then & Now!